Description

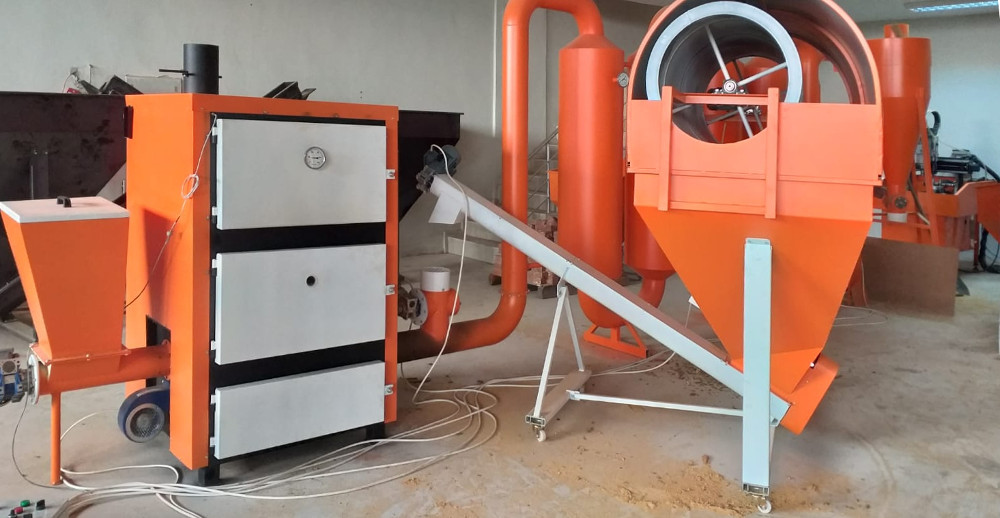

PM-3 Sawdust Fertilizer Feed Granule Pelletizing Machine

From PM-3 (4 Kw Mini Series) to PM-100 (100 Kw Power Series), pellet machines are used as chip pellet machines, fish bait pellet machines, manure pellet machines. Pellet machines are almost identical in appearance, but in technical details pellet machines differ according to the product to be pelletized. The most obvious features of these are engine power, perforated shafts and crushers. The engine power should grow parallel to the press power to be applied in pelletisation, the perforated shaft should be in different structures according to the product to be pelletized and the crushers should be designed accordingly.

What is the Pellet Machine Used for?

Pellet machines are used for pelletizing and tabletting of powdered raw materials. During this pelletising process, as in the example of sawdust, a pressure of 400 t/cm2 is applied between the perforated shaft and the press balls, depending on which product is to be pressed. During this pressure, an average of 60-70 degrees heat is generated in the pellet press machine.

Who is the Pellet Machine Preferred by?

Plants for the production of raw materials for wood and furniture production, plants for the production of animal feed and fertilisers, pelletising plants for the production of olive prina and cardboard newsprint, etc. are used in pelletising plants. According to the product to be pelletized, it is starting with 3KW (220V) home use machines and the range extends to 100KW (380V) pellet pressing machines.

Pellet Machine Mechanical Properties

– Special Series Pellet Reducer

– Heat Treated Pellet Press Balls

– Heat Treated Perforated Pellet Shaft

– Special Hole Shape According to the Product to be Pelleted

– Adjustable Length Cutters According to the Product to be Pelleted

– 2mm to +mm Pellet Press

– Robust Design Sheet Coating

– Static Oven Paint in Optional Color

Pellet Machine Automation Features

– Start – Stop with start and stop button

– Emergency Stop

– Forward and Backward (Optional)

– Automatic protection in case of entrapment (optional)

– Pellet Cooler, Pellet Mixer and Weighing Tracking System PLC (Optional)

Pellet Machine Extra Optional Features

– Pellet Cooling System

– Pellet Mixer

– Belt and Conveyor System with Desired Features for Pellet Press Factories

– Pellet Weighing Dosing System

– Pellet Bagging and Sacking System

Pellet Feed Machine Features

– Pellet feed machines provide great convenience in feed production, which is one of the biggest expenses of cattle and small cattle breeders.

– Pellet feed machines are a perfect solution for preserving the minerals and vitamins that should be in the feed. Eliminates the ability of animals to distinguish feed.

PP-2550 PP-2550 Electronic Pellet Weighing and Packing Machine

Feed Sawdust Fertilizer Granule Mdf Pellet Packing Machine, With the granule powder and granular product packaging machine, which is also used in various sectors and business areas, the weighing and packaging of the products according to the product you want, the sacks, bags and packaging process can be done more quickly and practically with the electronic plc system. It allows to prepare packs weighing 25 or 50kg. With different models and types, it can also be designed individually according to all kinds of usage areas.

What is the Purpose of a Pellet Packing Machine?

The pellet pressing process is carried out under control with certain automation controls in a certain sorting and cycle order. In the last of these stages the prepared pellet is weighed and packaged in determined kilos, and this is used to increase the workload and production volume.

Who Prefers Pellet Packing Machines?

Plants for the production of raw materials for wood and furniture production, plants for the production of animal feed and fertilisers, pelletising plants for the production of olive prina and cardboard newsprint, etc. are used in pelletising plants for packaging these products for storage and sale purposes after the pelletizing works. It is generally preferred by companies with high production capacity.

Mechanical Properties of Pellet Packing Machines

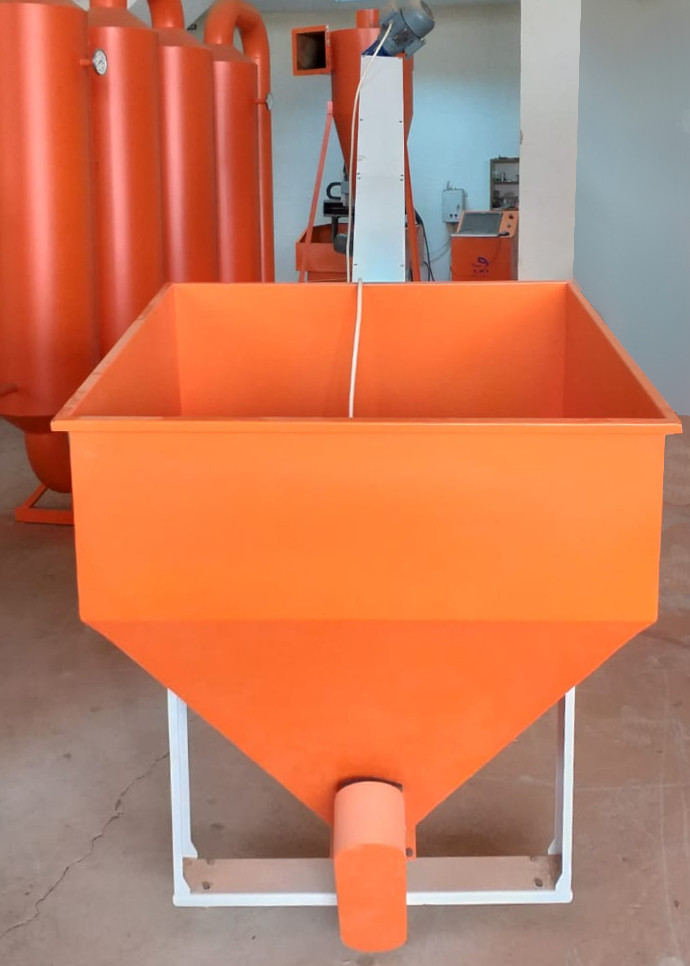

– Conveyor Feed Hopper

– Standard Filling Neck

– 25-50 Kg Shroud and Weighing Scale with Loadcell (Can be optionally increased)

– Special Tape System According to the Product to Pelletized

– Appropriate Bunker Structure According to the Product to be Pelleted

– 3mm Sheet Optional Chrome Body or Bunker

– Robust Design Sheet Coating

– Static Oven Paint in Optional Colour

Pellet Packing Machine Automation Features

– Start – Stop with start and stop button

– Emergency Stop

– Forward and Backward (Optional)

– Automatic protection in case of entrapment (optional)

– Pellet Cooler, Pellet Mixer and Weighing Tracking System Integration PLC (Optional)

Extra Optional Features

– Barcoding

– Special Sack Opening Sewing System

– Special Vacuum System

– Special Nylon Opening Adhesive System

– Truck Loading Conveyor

Features of Prina Pellet Machine

– The production of prina pellets is much easier than the production of sawdust pellets and is less expensive in terms of equipment.

– The production of sawdust pellets requires much more experience, while the production of pomegranate pellets requires only one machine and a helix.

– Thus, it is possible to start a business with a lower capital.

– There is no problem in the supplies of pellet raw materials in our country.

For example, a 30 Kw pellet machine can produce 250-350 kg of sawdust pellets per hour, while 400-700 kg of Prina pellets can be produced in the same time with the same machine.

– Clover Pellet production, which is rapidly adopted in our country as a result of environmental energy production, is becoming widespread day by day.

– Increasing feed costs force the breeders to produce their own feed.

– Clover Pellet Machines offer solutions suitable for the needs of breeders.

– We can produce clover pellet machines from 2.2 Kw to 30 Kw according to the needs of the capacities of our breeders.

– For more information about clover pellet production, you can call us and request a special custom pellet machine production.